Views: 39 Author: Site Editor Publish Time: 2018-10-25 Origin: www.fuchun-casting.com

Around the 21st century BC, China entered the Bronze Age, which saw the growth and maturity of a civilization that would be sustained in its essential aspects for another 2,000 years.

Yin-Shang bronzes mark a peak in the late Bronze Age all over the world, with a variety of fine bronze wares, e.g., the 832.84 kilogram giant Houmuwu Ding bronze vessel of 133 centimeter height, 110 centimeter length, and 79 centimeter width.They were cast in a great variety of sophisticated shapes, mythical animals, natural objects and beautiful designs. Bronze wares have been found in the middle and lower reaches of the Yellow River and Yangtze Rivers and some remote border areas. Many of the bronze wares have names and/or stories written on them in ancient Chinese characters, providing key evidences for the well-developed Yin-Shang bronze civilization and history of China.

Seeing here,we all have a question, in that era of low productivity, how did the ancients make bronzes, and how did they achieve exquisite shapes?

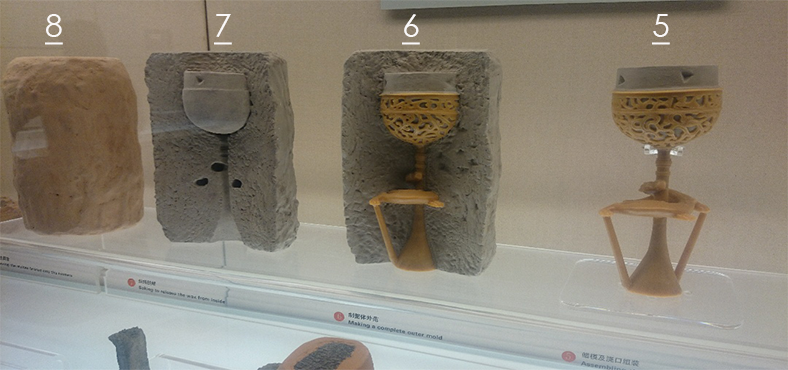

The earliest Chinese bronzes were made by the method known as piece-mold casting—as opposed to the lost-wax method, which was used in all other Bronze Age cultures. In piece-mold casting, a model is made of the object to be cast, and a clay mold taken of the model. The mold is then cut in sections to release the model, and the sections are reassembled after firing to form the mold for casting. If the object to be cast is a vessel, a core has to be placed inside the mold to provide the vessel’s cavity. The piece-mold method was most likely the only one used in China until at least the end of the Shang dynasty. An advantage of this rather cumbersome way of casting bronze was that the decorative patterns could be carved or stamped directly on the inner surface of the mold before it was fired. This technique enabled the bronzeworker to achieve a high degree of sharpness and definition in even the most intricate designs.

Bronze wares, as precious metal wares, were mainly used for ceremonial purposes by the upper class in ancient China. The variety and quantity of the bronzes that were used were a reflection of the owner's social status and power. Bronze technology is one of the most important achievements of Chinese civilization.