- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

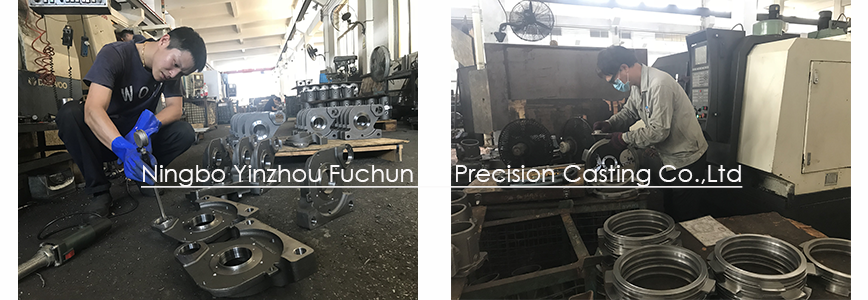

Views: 72 Author: Site Editor Publish Time: 2018-02-01 Origin: www.fuchun-casting.com

Precision casting is widely used in jet engines, gas turbines, steam turbines, aircraft parts, internal combustion engines, vehicles, food machinery, printing machinery, paper machinery, compressors, valves, pumps, meters, sewing machines, weapons, business machines, and other machine parts.

Generally speaking, the dimensional accuracy of precision casting is affected by many factors, such as casting structure, casting material, mould making, shell making, roasting, pouring, etc. Any unreasonable link setting and operation will change the shrinkage rate of casting, resulting in deviation of the dimensional accuracy and requirements of casting. The following factors can cause defects in dimensional accuracy of precision castings:

1. The higher the pouring temperature, the greater the shrinkage during cooling. The lower the temperature, the smaller the shrinkage.

2. The larger the wall thickness is, the larger the shrinkage rate is, and the thickness of the wax increases when the wall thickness increases. Wax / casting shrinkage is large, hindering shrinkage.

3. Zirconium sand and zirconium powder are little affected by temperature, but the change of shell thickness will hinder the shrinkage of castings. The thicker the shell is, the smaller the shrinkage is, the thinner the shell is, and the larger the shrinkage rate is.

4. The size change caused by shell roasting can be neglected, but the shell deformation during shell roasting, the shell swelling caused by dewaxing and the floating core produced during pouring process will seriously reduce the size tolerance grade of castings.

5. The higher the carbon content is, the smaller the linear shrinkage is, the lower the carbon content is, and the larger the shrinkage is. At the same time, different alloying elements also affect the linear shrinkage of castings when alloying elements are added.

This is where a batch of steel meets more than one specification or grade. It is a way of allowing melting shops to produce stainless steel more efficiently by restricting the number of different types of steel. The chemical composition and mechanical properties of the steel can meet more than one grade within the same standard or across a number of standards. This also allows stockholders to minimise stock levels.

For example, it is common for 1.4401 and 1.4404 (316 and 316L) to be dual certified - that is the carbon content is less than 0.030%. Steel certified to both European and US standards is also common.

There are many different types of surface finish on stainless steel. Some of these originate from the mill but many are applied later during processing, for example polished, brushed, blasted, etched and coloured finishes.

The importance of surface finish in determining the corrosion resistance of the stainless steel surface cannot be overemphasised. A rough surface finish can effectively lower the corrosion resistance to that of a lower grade of stainless steel.

Various types of stainless steel are used across the whole temperature range from ambient to 1100 deg C. The choice of grade depends on several factors:

In the European standards, a distinction is made between stainless steels and heat-resisting steels. However, this distinction is often blurred and it is useful to consider them as one range of steels.

Increasing amounts of Chromium and silicon impart greater oxidation resistance. Increasing amounts of Nickel impart greater carburisation resistance.

Austenitic stainless steels are extensively used for service down to as low as liquid helium temperature (-269 deg C). This is largely due to the lack of a clearly defined transition from ductile to brittle fracture in impact toughness testing.

Toughness is measured by impacting a small sample with a swinging hammer. The distance which the hammer swings after impact is a measure of the toughness. The shorter the distance, the tougher the steel as the energy of the hammer is absorbed by the sample. Toughness is measured in Joules (J). Minimum values of toughness are specified for different applications. A value of 40 J is regarded as reasonable for most service conditions.

Steels with ferritic or martensitic structures show a sudden change from ductile (safe) to brittle (unsafe) fracture over a small temperature difference. Even the best of these steels show this behaviour at temperatures higher than -100 deg C and in many cases only just below zero.

In contrast austenitic steels only show a gradual fall in the impact toughness value and are still well above 100 J at -196 deg C.

Another factor in affecting the choice of steel at low temperature is the ability to resist transformation from austenite to martensite.

It is commonly stated that “stainless steel is non-magnetic”. This is not strictly true and the real situation is rather more complicated. The degree of magnetic response or magnetic permeability is derived from the microstructure of the steel. A totally non-magnetic material has a relative magnetic permeability of 1. Austenitic structures are totally non-magnetic and so a 100% austenitic stainless steel would have a permeability of 1. In practice this is not achieved. There is always a small amount of ferrite and/or martensite in the steel and so permeability values are always above 1. Typical values for standard austenitic stainless steels can be in the order of 1.05 – 1.1.

It is possible for the magnetic permeability of austenitic steels to be changed during processing. For example, cold work and welding are liable to increase the amount of martensite and ferrite respectively in the steel. A familiar example is in a stainless steel sink where the flat drainer has little magnetic response whereas the pressed bowl has a higher response due to the formation of martensite particularly in the corners.

In practical terms, austenitic stainless steels are used for “non-magnetic” applications, for example magnetic resonance imaging (MRI). In these cases, it is often necessary to agree a maximum magnetic permeability between customer and supplier. It can be as low as 1.004.

Martensitic, ferritic, duplex and precipitation hardening steels are magnetic.