Views: 39 Author: Site Editor Publish Time: 2019-06-17 Origin: www.fuchun-casting.com

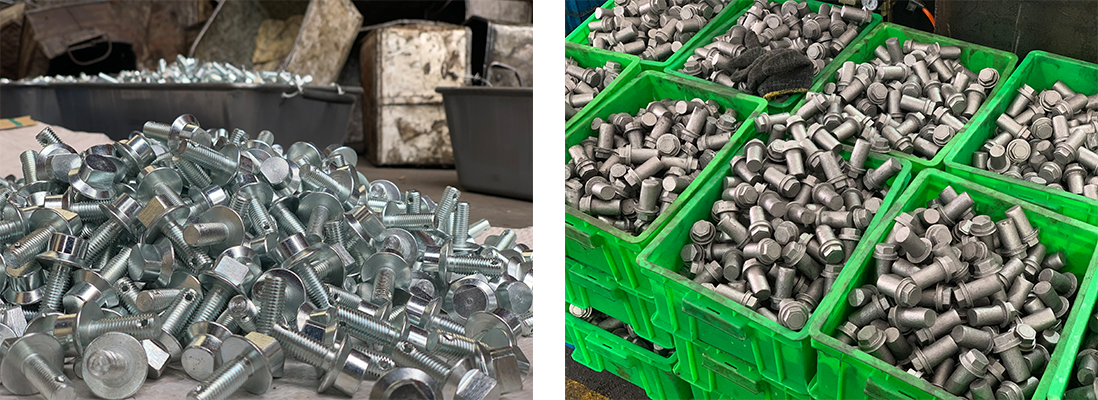

Fasteners are a kind of mechanical parts which are widely used for fastening connections. A variety of fasteners can be seen on various machinery, equipment, vehicles, ships, railways, bridges, buildings, structures, tools, instruments, instruments and supplies.

Fasteners in almost all industries are made of carbon steel and alloy steel. Some kinds of fasteners hope to prevent corrosion. Even if fasteners with anticorrosive materials are used, proper surface treatment is still needed to prevent corrosion of different materials.

Steel fasteners can be electro-plated with zinc for better corrosion resistance and usually to a thickness of 200 – 300 micro inches (.0002" - .0003"). Fasteners that have been zinc plated have a shiny silver finish. It is a sacrificial finish that by forming a “galvanic cell” corrodes before the underlying steel. Zinc plated fasteners are fairly corrosion resistant but will rust over time and quicker if the coating is damaged or if exposed to harsh elements (eg marine environments). Plating of this kind will probably provide no more than 12 hours of salt spray protection. The corrosion resistance of zinc depends on the thickness of the coating and can be further increased by applying a conversion coating. A zinc finish also provides some esthetic value, increases abrasion resistance and provides a excellent bonding surface for painting.

Phosphating also known as Parkerization, is a chemical phosphate conversion coating process whereby a microscopic layer of iron is removed and replaced with a comparably thin layer of either zinc or manganese dioxide to make the steel substrate more corrosion and wear resistant. The final result is an attractive and durable grey-black finish. The Parkerizing process is not possible with non-ferrous metals such as aluminum, brass, or copper. Nor can it be applied to steels containing large amounts of nickel, or on stainless steel. Black phosphate coating is often used to enhance corrosion resistance. However, phosphate coating by itself does not provide protection because of the porous nature of the coating.

Therefore, additional treatment with oil or other sealers are used to attain a moderate level of corrosion resistance.

Phosphate coatings are typically used to help break in components subject to wear and help prevent galling. It is also used to prepare surfaces for further coating and/or painting. The porous nature of the phosphate finish allows materials to seep into the coating thereby providing an excellent adhesion base for secondary treatments. Furthermore the chemical nature of the coating electrically isolates the surface of the part which reduces corrosion that tends to occurs at the metal and paint/coating interface.

Cadmium plating provides excellent corrosion resistance even in harsh environments (eg salt atmospheres). It provides good paint base due to excellent paint adhesion properties, and it is more resistant to stripping than zinc plating.

Cadmium is also excellent for plating stainless steel, and with aluminum to prevent galvanic corrosion. Cadmium plating is generally bright silvery white in appearance. Further treating can produce an iridescent, black, golden, amber or olive appearance and increase corrosion resistance.

Chrome is used in plating fasteners primarily for esthetics purposes. It provides comparable corrosion resistance to zinc plating, but at a much higher cost. If more corrosion resistance is required stainless steel may be chrome plated,preventing any corrosion should the chrome be damaged.

Depending on the process used and intended application, nickel can be deposited soft or hard, dull or bright. Nickel plating is often applied for a decorative finish. Bright nickel plating is a highly reflective finish similar to stainless steel, but is very hard with relatively poor ductility. Therefore, parts should be formed into final shape before being plated with bright nickel. Soft nickel plating (semi-bright or dull nickel) has a more satiny finish than does bright nickel, and is more ductile.

Items that may undergo heat shock or minor bending should be plated with soft nickel to reduce the possibility of the plating peeling or flaking off.

Nickel plating on fasteners is mainly used in places where corrosion protection and good conductivity are required.

Hot-dip galvanizing of fasteners are carbon steel fasteners into the heat of approximately 510 ° c dissolves zinc plated tank so that fastener on the surface of Fe-Zn alloy into the passivation of zinc, resulting in surface treatments. Fasteners of hot-dip galvanized price is higher than that of electroplating.

There is no hydrogen embrittlement problem. Without considering the environmental protection of hexavalent chromium, it is actually most suitable for high strength fasteners with high anticorrosion requirements.

Fasteners, as one of the products with large import and export volume in China, are of great practical and strategic significance to promote Chinese firms to enter the world and to promote their full participation in international cooperation and competition.

Besides casting materials, what causes the casting dimensional accuracy?

The cause of the surface blister of zinc alloy precision casting

Mechanical properties and machining requirements of stainless steel precision casting

What is the development status and future of agricultural machinery in China?

Do you think Metal 3D Printing will replace traditional casting technology?

Stainless steel precision casting temperature control and mold use