Views: 27 Author: Site Editor Publish Time: 2018-08-10 Origin: www.fuchun-casting.com

A CNC, or computer numerical control machine is a high precision tool that’s computer-controlled and makes repeated, accurate movements. It does so by taking computer-generated code and converting it with software to electrical signals. The signals are what control the CNC motors and directs them to move in small increments that are highly precise and repetitive.

CNC (Computer Numerical Control) machining is a subtractive manufacturing technology. This means that parts are created by removing material from a solid block (called the blank or the workpiece) using a variety of cutting tools.

A CNC machine removes material from a solid block using a variety of cutting tools to produce a part based on a CAD model.

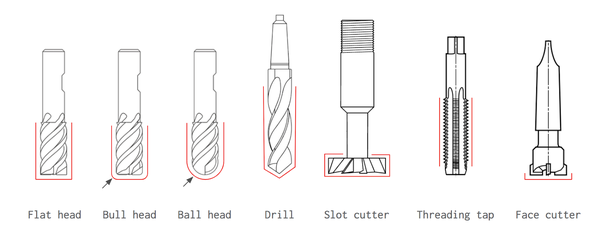

To create different geometries, CNC machines use different cutting tools. Their different geometry allows the machining of features with different details.

CNC milling and CNC turning machines are examples of 3-axis CNC systems. These “basic” machines allow the movement of the cutting tool in three linear axes relative to the workpiece (left-right, back-forth and up-down).

The advanced multi-axis CNC machining centers come in three variations: 5-axis indexed CNC milling, continuous 5-axis CNC milling and mill-turning centers with live tooling. These systems are essentially milling machines or lathes enhanced with additional degrees of freedom. For example, 5-axis CNC milling centers allow the rotation of the machine bed or the toolhead (or both) in addition to the three linear axes of movement.

A portion of the basic machine devices that can keep running on the CNC are: Lathe, Milling machines, Drilling Machine and so on. The principle reason for these machines is to evacuate a portion of the metal to give it appropriate shape, for example, round, rectangular, and so forth. In the customary strategies these machines are worked by the administrators who are specialists in the operation of these machines. The greater part of the employments should be machined precisely, and the administrator ought to be master enough to make the exactness occupations. In the CNC machines the part of the administrators is limited. The administrator needs to simply nourish the program of directions in the PC, stack the required devices in the machine, and rest of the work is finished by the PC naturally. The PC guides the machine apparatus to perform different machining operations according to the program of guidelines nourished by the administrator.

Sections of this article have been taken from www.3dhubs.com/guides/cnc-machining/#basics

Besides casting materials, what causes the casting dimensional accuracy?

The cause of the surface blister of zinc alloy precision casting

Mechanical properties and machining requirements of stainless steel precision casting

What is the development status and future of agricultural machinery in China?

Do you think Metal 3D Printing will replace traditional casting technology?

Stainless steel precision casting temperature control and mold use

Is it possible to print high-speed rail with 3D printing technology?