Views: 32 Author: Site Editor Publish Time: 2019-06-14 Origin: www.fuchun-casting.com

The safe and stable operation of the train can not be separated from 24 hours of maintenance guarantee every day. When the replacement parts are needed and no replacement parts can be found, the railway department should contact the manufacturer to provide them quickly. At this time, the cost of vehicle management and spare parts procurement will be relatively high.

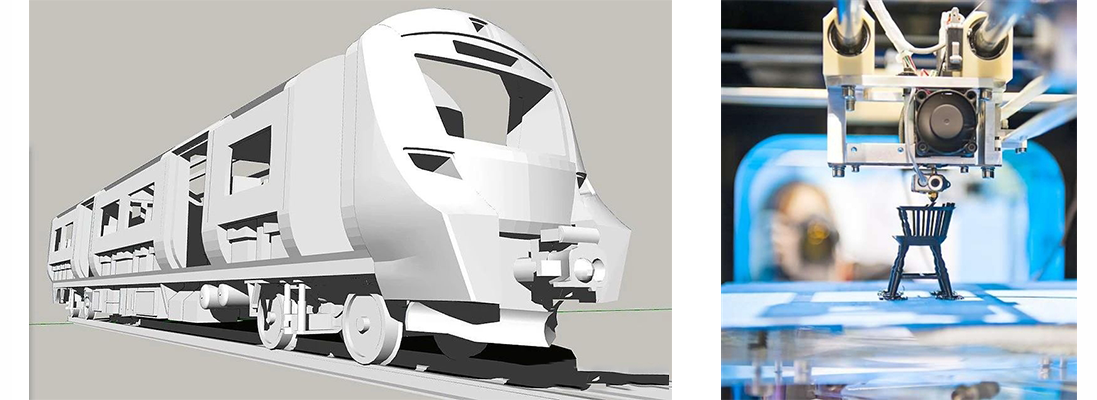

In recent years, with the rapid development of 3D printing technology, it is faster and more economical to use 3D printing to assist train operation and maintenance, provide customized parts and replace damaged parts at any time.

The greatest advantage of 3D printing is that it can generate any shape parts directly from computer graphics data without machining or any die.

Thus greatly shorten the production cycle of products, improve production efficiency and reduce production costs.

At the same time, 3D printing can also print out some shapes that traditional production technology can not produce, and can simplify the whole production process, with the characteristics of fast and effective.

In the future, the cost of replacing parts and tools in 3D printing will be reduced by 95% compared with traditional manufacturing time.

As early as 2013, American railway operators first used 3D printing technology. They invented a hand-held automatic identification device to track vehicles and ensure that they were assembled in the right order.

A team of researchers at the University of Birmingham in the United Kingdom is also studying the use of 3D printing technology to automate repair by adding materials to the wheel surface to repair when damage is detected. By shortening the inspection time and prolonging the life of wheelset, it is possible to reduce the maintenance cost of train.

Deutsche Bank (DB), Europe's largest railway operator, launched 3D printing parts in 2016 and has produced three types of railway spare parts, namely headrest, ventilation grille and Braille sign.

With the deepening of exploration, it is expected that the future 3D printing technology combined with rapid digital modeling will penetrate into the manufacturing of more spare parts for high-speed railway operation and maintenance.

As the core manufacturer of high-speed railway, Siemens first opened the first "digital maintenance center" in Germany. The maintenance station aims to achieve the highest level of digitization in the railway industry. At present, a 3D printer for metal melt deposition modeling has been deployed.

Siemens expects about 100 trains to enter the plant every month for maintenance, while the ability to replace parts and tools with 3D printing reduces manufacturing time by 95%. They can optimize spare parts with lower cost and shorter time to achieve longer life cycle.

Facts have proved that 3D printing plays a very important role in railway operation and maintenance. By using 3D printing technology to produce spare parts, the train can run faster and inventory can be reduced.With the development of science and technology, it can be expected that 3D printing will have a wider space in the railway field.

Besides casting materials, what causes the casting dimensional accuracy?

The cause of the surface blister of zinc alloy precision casting

Mechanical properties and machining requirements of stainless steel precision casting

What is the development status and future of agricultural machinery in China?

Do you think Metal 3D Printing will replace traditional casting technology?

Stainless steel precision casting temperature control and mold use