Views: 27 Author: Site Editor Publish Time: 2018-11-11 Origin: www.fuchun-casting.com

Automotive hub is an important part of automotive. With the growth of China's automotive parts industry, the hub industry has gradually developed and expanded.

Hubs on the market can be divided into steel hubs and alloy hubs according to their materials, each with advantages and disadvantages.

The main advantage of steel hub is that the manufacturing process is simple (usually casting process) cost is relatively low, and the ability to resist metal fatigue is very strong, which is commonly known as cheap and strong. But the disadvantages of steel hub are ugly appearance, heavy weight (the same hub steel is much heavier than aluminum alloy), large inertia resistance, poor heat dissipation, and very easy to rust.

Alloy hub can make up for above problem, lighter weight, less inertia resistance, high manufacturing accuracy, small deformation at high speed, less inertia resistance, which is conducive to improve the straight-line driving performance of the car, reduce tire rolling resistance, thereby reducing fuel consumption.

At the same time, we also have a question, why are automobiles usually 7 spokes hub, 7 for 360 degrees is also a fundamentally irreducible angle, is it not troublesome in production?

In fact, this is a structural design to avoid deformation and cracks in casting manufacturing.When designing wheel spokes, we should try our best to make them shrink freely so as not to cause cracks.

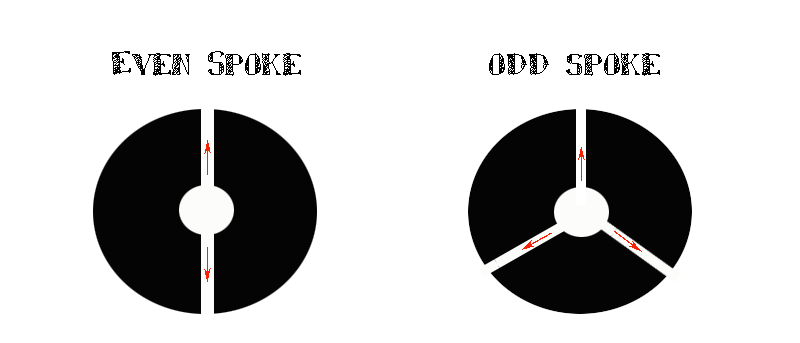

If the spokes of wheels are even, the spokes are easy to shape, but each spoke is arranged in a straight line with the other. When the wheels are manufactured in the cooling process, they are restrained and blocked each other during shrinkage, and the internal stress is too large to cause cracks.

So in practice, we will use curved spoke or odd spoke design, which can relieve internal stress by means of micro-deformation of spoke or rim, thus reducing the risk of cracking.

Besides casting materials, what causes the casting dimensional accuracy?

The cause of the surface blister of zinc alloy precision casting

Mechanical properties and machining requirements of stainless steel precision casting

What is the development status and future of agricultural machinery in China?

Do you think Metal 3D Printing will replace traditional casting technology?

Stainless steel precision casting temperature control and mold use