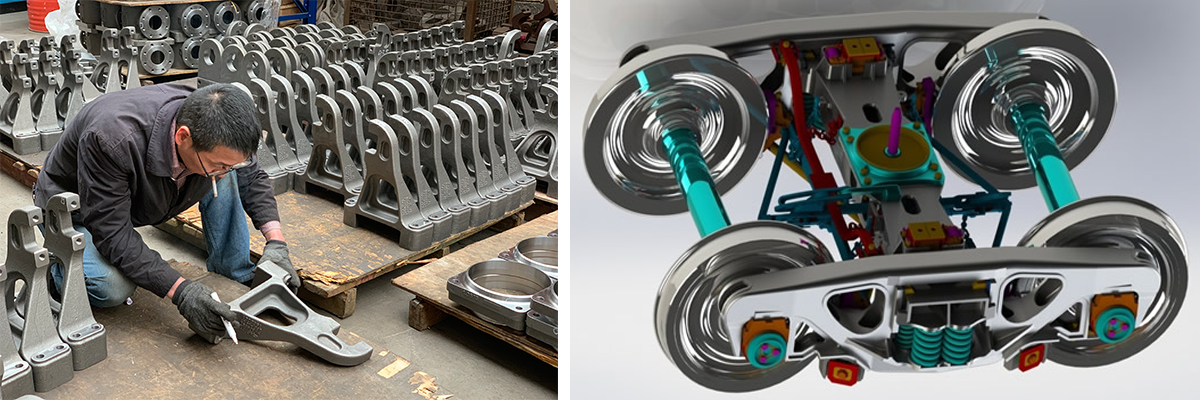

FC Precision Casting

| Availability: | |

|---|---|

| Quantity: | |

Detailed Feature:

| Product Name | High Quality OEM Precision Casting Customized Train Bogie Parts | ||||

| Precision Processing | OEM | |||||

| Tolerance/Precision | CT9 | |||||

| Product Materials | Steel, Iron, Steel, Gray Iron,Nodular Cast Iron | |||||

| Process Technology | Precision Casting | |||||

| Surface Treatment | Machining Or Spay Painting | |||||

| Size | Customed | |||||

| Anti-rust | Antirust oil | |||||

| File Formats | PDF,Auto CAD, Solid work,JPG,Pro E | |||||

| FOB Port | Ningbo Or Shanghai | |||||

Applications:

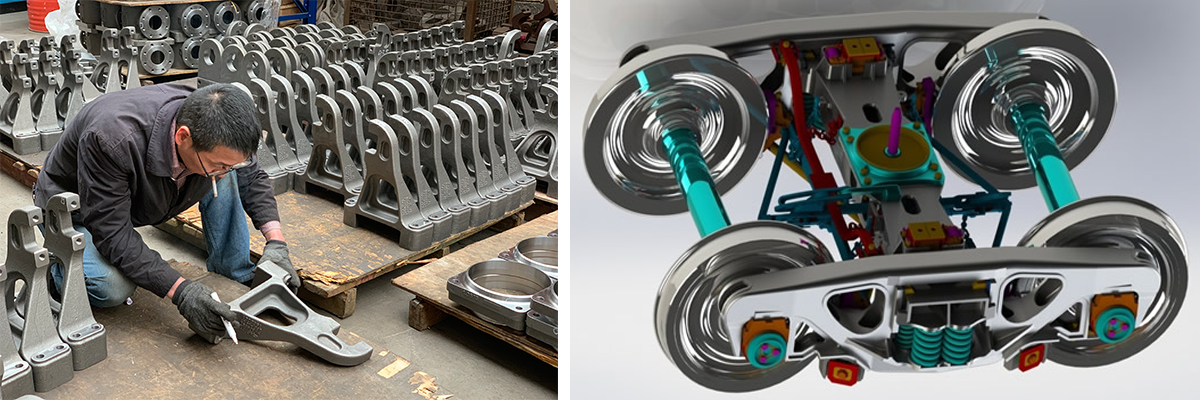

Railway bogies are hardly noticed by the average passenger but they are an essential part of the the train, its drive system and its guidance mechanism. A standard railway vehicle will have two bogies, generally located near the vehicles ends. Each bogie is a 4-wheeled or 6-wheeled truck that provides the support for the vehicle body and which is used to provide its traction and braking. Each carriage has two bogies. The bogies support the mass of the vehicle, use the wheels to guide it along the track and provide some degree of cushioning against the shocks transmitted from the track during motion.

Bogies serve a number of purposes:

Support of the rail vehicle body;

Stability on both straight and curved track;

Improve ride quality by absorbing vibration and minimizing the impact of centrifugal forces when the train runs on curves at high speed;

Minimizing generation of track irregularities and rail abrasion.

The Bogie Frame is one of the main components of the bogie.This can be of inside frame type where the main frame and bearings are between the wheels, or (more commonly) of outside frame type where the main frame and bearings are outside the wheels.

Advantages:

★ Professional technical team provides high quality technical supporting;

★ High quality materials can increase service life;

★ Precision control of size makes assembly more reasonable and perform more efficiently.

Detailed Feature:

| Product Name | High Quality OEM Precision Casting Customized Train Bogie Parts | ||||

| Precision Processing | OEM | |||||

| Tolerance/Precision | CT9 | |||||

| Product Materials | Steel, Iron, Steel, Gray Iron,Nodular Cast Iron | |||||

| Process Technology | Precision Casting | |||||

| Surface Treatment | Machining Or Spay Painting | |||||

| Size | Customed | |||||

| Anti-rust | Antirust oil | |||||

| File Formats | PDF,Auto CAD, Solid work,JPG,Pro E | |||||

| FOB Port | Ningbo Or Shanghai | |||||

Applications:

Railway bogies are hardly noticed by the average passenger but they are an essential part of the the train, its drive system and its guidance mechanism. A standard railway vehicle will have two bogies, generally located near the vehicles ends. Each bogie is a 4-wheeled or 6-wheeled truck that provides the support for the vehicle body and which is used to provide its traction and braking. Each carriage has two bogies. The bogies support the mass of the vehicle, use the wheels to guide it along the track and provide some degree of cushioning against the shocks transmitted from the track during motion.

Bogies serve a number of purposes:

Support of the rail vehicle body;

Stability on both straight and curved track;

Improve ride quality by absorbing vibration and minimizing the impact of centrifugal forces when the train runs on curves at high speed;

Minimizing generation of track irregularities and rail abrasion.

The Bogie Frame is one of the main components of the bogie.This can be of inside frame type where the main frame and bearings are between the wheels, or (more commonly) of outside frame type where the main frame and bearings are outside the wheels.

Advantages:

★ Professional technical team provides high quality technical supporting;

★ High quality materials can increase service life;

★ Precision control of size makes assembly more reasonable and perform more efficiently.

Company Information:

Ningbo Yinzhou Fuchun Precision Casting Co., Ltd was set up in 1988, located in the beautiful coastal city of Ningbo, on China's eastern seaboard. One of the leading foundries in China, we specialize in casting of carbon steel, alloy steel, gray steel, stainless steel and ductile iron materials. With an annual output capacity of 10000 metric tons, our products range from 100 grams to 600 kilograms in weight.

We also produce mechanical parts for worldwide purchasers and can manufacture as per customers' drawings. Until now, our products can be mainly put into the following categories: valve parts, parts for rail and subways, parts for mining machinery, automobile fittings, parts for hydraulic machinery, parts for project machinery and other parts.

With 7 medium frequency electric furnaces for production, we also have spectrographs, metallographic analyzers, hardness testers, ultrasonic test machines, magnetic particle flaw detectors, impact testers, tension testers and other inspection instruments.

Furthermore, our machining capability is very strong, with a whole line of boring, milling and drilling lathes, 13 CNC lathes, 4 CNC machining centers, and related metallurgical machinery.

Our Services:

| ❤ Satisfied Quality; |

| ❤ Competitive Price; | |

| ❤ Professional Sales & QC Team; | |

| ❤ Quick Delivery; | |

| ❤ Perfect After-sales Service. |

We believe that good quality and honesty help us win customers. We are looking forward to working with you and establishing mutually beneficial business relationships with you. If you are interested in our products, please feel free to contact us for more details.

Company Information:

Ningbo Yinzhou Fuchun Precision Casting Co., Ltd was set up in 1988, located in the beautiful coastal city of Ningbo, on China's eastern seaboard. One of the leading foundries in China, we specialize in casting of carbon steel, alloy steel, gray steel, stainless steel and ductile iron materials. With an annual output capacity of 10000 metric tons, our products range from 100 grams to 600 kilograms in weight.

We also produce mechanical parts for worldwide purchasers and can manufacture as per customers' drawings. Until now, our products can be mainly put into the following categories: valve parts, parts for rail and subways, parts for mining machinery, automobile fittings, parts for hydraulic machinery, parts for project machinery and other parts.

With 7 medium frequency electric furnaces for production, we also have spectrographs, metallographic analyzers, hardness testers, ultrasonic test machines, magnetic particle flaw detectors, impact testers, tension testers and other inspection instruments.

Furthermore, our machining capability is very strong, with a whole line of boring, milling and drilling lathes, 13 CNC lathes, 4 CNC machining centers, and related metallurgical machinery.

Our Services:

| ❤ Satisfied Quality; |

| ❤ Competitive Price; | |

| ❤ Professional Sales & QC Team; | |

| ❤ Quick Delivery; | |

| ❤ Perfect After-sales Service. |

We believe that good quality and honesty help us win customers. We are looking forward to working with you and establishing mutually beneficial business relationships with you. If you are interested in our products, please feel free to contact us for more details.

Certification Introduction:

Ningbo Yinzhou Fuchun Precision Casting Co., Ltd put great emphasis on our quality control system to assure our products have the best quality. We have already passed ISO9001, TUV-PED and BV approvals. 80% of our products are exported to Europe, the USA, and Australia where they are well received by customers, with whom we have established long term business relationships.

Certification Display:

Certification Introduction:

Ningbo Yinzhou Fuchun Precision Casting Co., Ltd put great emphasis on our quality control system to assure our products have the best quality. We have already passed ISO9001, TUV-PED and BV approvals. 80% of our products are exported to Europe, the USA, and Australia where they are well received by customers, with whom we have established long term business relationships.

Certification Display:

Packaging Display:

| Wooden box with plastic bag; |

| EUR-pallet with pallet collar and plastic bag; | |

As customer's requirements. |

Transport Details:

All kinds delivery way we can satisfy as customer's require.

Packaging Display:

| Wooden box with plastic bag; |

| EUR-pallet with pallet collar and plastic bag; | |

As customer's requirements. |

Transport Details:

All kinds delivery way we can satisfy as customer's require.

One-Stop Custom Casting & OEM Manufacturing