Views: 21 Author: Site Editor Publish Time: 2019-04-12 Origin: www.fuchun-casting.com

There have been huge developments in the field of science and technology in the past few decades.With the introduction of hybrid, full electric, and even hydrogen vehicles, our vehicles will continue to get more complex. That trend doesn’t seem to be slowing down anytime soon. Like all other aspects of life, the processes in the automobile industry have been changed drastically through this development.

Limited to the category of cars, sometimes you can see the grade of a car at a glance. Why does it make such a big difference in appearance? Does exquisite appearance of a car add a lot of cost?

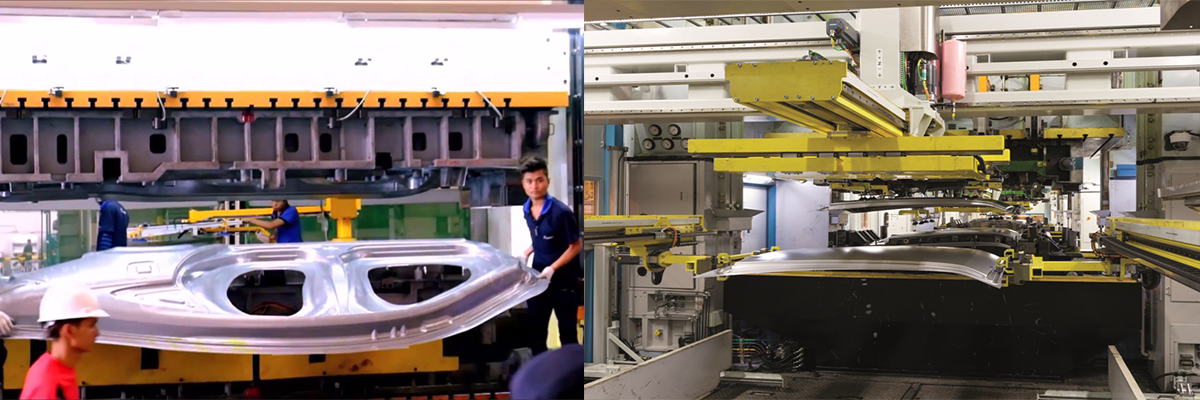

Why choose the car below 50W, generally speaking, the annual output of the car below 50W is usually higher, and the stamping accuracy of parts will become worse and worse under the high-speed and large-scale operation of automation line. The precision requirement of these models in the process of die making is very high, but also requires the die to have certain strength, stiffness and better robustness.On the contrary, due to the low output and stable stamping of high-end models, the die does not need to be debugged frequently in the production process, and it is slightly less difficult for manufacturing and workers to debug.

From personal experience, it is not always the better-looking car panels stamping will be more complex, many times the uglier car panels stamping will be more difficult.The appearance of automobile is determined by the appearance of the panel. In many cases, the internal shape determines the stamping difficulty of the panel and the manufacturing cost of the mould.

The manufacturing cost of the mould will not have a great impact on the appearance of the car. Personally, I think the inner size of the car is the main obstacle to restrict the aesthetic feeling of the car appearance.

In many cases, we can judge whether a car is high-end or not by its shape and size. From small cars, medium and high-grade cars to the best high-grade cars, the shape is getting bigger and bigger, and the wheelbase is getting wider and wider. The bigger the shape and the wider the wheelbase, the bigger the space of body design, and the more adjustable the matching relationship between parts.

Similarly, because joint ventures have a lot of design experience and a high level of industrial design, they can usually design more mature parts, i.e. beautiful exterior stamping with simpler panels.We often say that some of the ugly models are usually those smaller cars. Because of the overall cost of making the car, they have smaller dimensions. They can not extract the essence of design from high-end models well, which leads to a lot of ugly car appearance.

The price of stamping materials may not vary much in unit price, but once the total number increases, the difference in total price will be particularly obvious.This difference in cost and overall technology leads to poor quality of materials used in low-end vehicles, high stamping difficulty and low precision of stamping dimension. Low-end vehicles often avoid some complex shapes and try to use simple lines and smooth surfaces when they design after many losses. In this state, the appearance of the car is easy to cause rigidity, lack of vitality and single lines.

Besides casting materials, what causes the casting dimensional accuracy?

The cause of the surface blister of zinc alloy precision casting

Mechanical properties and machining requirements of stainless steel precision casting

What is the development status and future of agricultural machinery in China?

Do you think Metal 3D Printing will replace traditional casting technology?

Stainless steel precision casting temperature control and mold use