Views: 31 Author: Site Editor Publish Time: 2019-08-26 Origin: www.fuchun-casting.com

Is your excavator moving slower than usual? Hearing strange noises from the hydraulic pump?

These might be more than just minor annoyances—they could be your hydraulic system's final cry for help before a catastrophic and expensive failure.

In construction and heavy machinery, hydraulic system failures account for a significant portion of unscheduled downtime and repair costs. The good news? These systems rarely fail without warning. By understanding and recognizing the early symptoms, operators and maintenance teams can move from reactive repairs to proactive, cost-saving prevention.

This guide outlines the 7 most critical warning signs of impending hydraulic system failure, explains their common causes, and provides practical steps you can take to address them before they lead to a complete breakdown.

Catching these signs early is the key to preventing major repairs.

Your hydraulic system shouldn't sound like a coffee grinder. New or changing noises are often the first clue.

What to Listen For:

Cavitation (A high-pitched whine or scream): Often caused by a clogged inlet filter, restricted suction line, or low oil level. Air bubbles form and implode inside the pump, causing severe damage.

Aeration (A loud knocking or rattling): Sounds like marbles in the pump. This means air is entering the system through leaks in the suction line, poor shaft seals, or low fluid levels.

Increased Pump Whine or Groaning: Can indicate worn internal components (pistons, vanes, gears) or severely contaminated, aged fluid with the wrong viscosity.

User Search Intent Insight: People often search for "hydraulic pump noisy", "whining noise from hydraulic system", or "hydraulic cavitation sound".

When cylinders extend sluggishly or loads feel heavier, your system is telling you it's losing efficiency.

What it Means: This typically points to internal leakage or pressure loss. Worn pump components, failing cylinder seals, or a malfunctioning relief valve can allow pressurized fluid to bypass where it's supposed to go, robbing the system of power and speed.

Simple Check: Can the system lift its rated load? Does it "drift" or sag under pressure? These are clear indicators.

User Search Intent Insight: Common queries include "excavator hydraulic weak", "hydraulic cylinder slow to extend", and "loss of hydraulic power".

While some heat is normal, excessive temperature (consistently above 180°F / 82°C) is a major red flag.

Why It's Dangerous: Heat breaks down hydraulic oil, destroys seals, and accelerates wear on all components.

Common Culprits:

Internal Leakage: The primary cause. Fluid leaking across worn parts creates friction and heat.

Blocked or Dirty Coolers: Fins clogged with dirt prevent proper heat exchange.

Incorrect Oil Viscosity: Oil that's too thick creates excess friction; oil that's too thin leads to internal leakage.

Relief Valve Stuck Open: Continuously dumps fluid, generating immense heat.

User Search Intent Insight: Searches like "hydraulic oil too hot", "causes of hydraulic overheating", and "hydraulic system running hot" are very common.

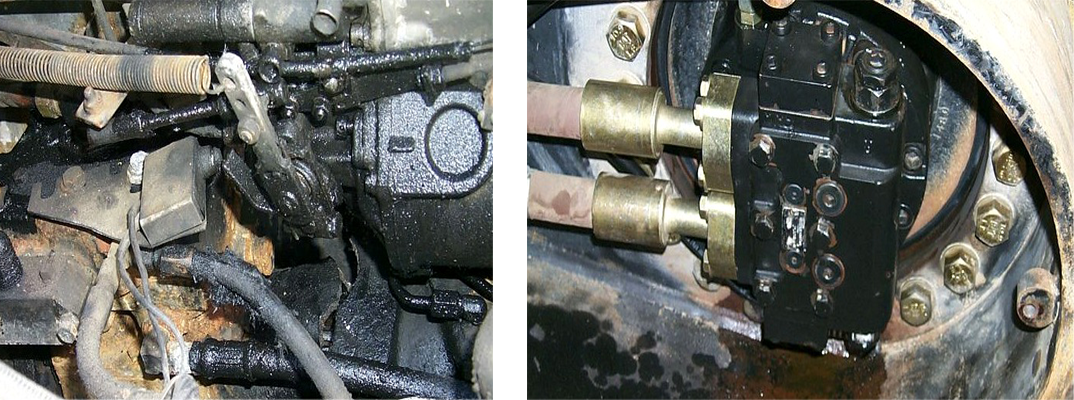

External Leaks: Puddles, drips, or wet spots around hoses, fittings, cylinders, and the pump. Don't ignore small seeps—they grow and indicate failing seals.

Internal Leaks: More sinister and harder to detect. Symptoms include poor performance and overheating, as mentioned above. A cylinder that creeps down when holding a load is a classic sign of internal seal leakage.

User Search Intent Insight: People search for "hydraulic cylinder leaking", "how to fix hydraulic leaks", and "hydraulic seal failure symptoms".

Your hydraulic oil should be relatively clean and clear. Check it regularly.

Warning Signs in the Oil:

Discolored/Milky Oil: Indicates water contamination, leading to corrosion and poor lubrication.

Dark, Murky, or Smelly Oil: Sign of severe oxidation, overheating, or breakdown.

Visible Metal Particles: A sign of significant internal wear (pump, valve, motor failure).

User Search Intent Insight: "Hydraulic oil color meaning", "water in hydraulic oil symptoms", "how to check hydraulic fluid".

If cylinders or motors "jerk," "chatter," or "creep" instead of moving smoothly, the system is unstable.

Likely Causes: Air in the system (aeration), severely contaminated fluid causing valve spools to stick, or a failing pump providing uneven flow.

User Search Intent Insight: "Hydraulic cylinder jerky movement", "what is hydraulic cylinder chatter", "air in hydraulic system symptoms".

A distinct burning odor is a serious, late-stage warning.

Immediate Action Required: This often signals an overheated and failing electric motor driving the pump, burning electrical insulation on solenoid coils, or severely carbonized/cooked hydraulic oil and seals. Shut down and investigate immediately.

Turn warning signs into preventive action. Incorporate these simple checks:

Visual/Leak Check: Walk around the machine. Look for fresh oil leaks, damaged hoses, and loose fittings.

Auditory Check: Listen for new or changed pump and system noises at start-up and during operation.

Temperature Check: Use an infrared thermometer to spot-check the pump, valve bank, and reservoir temperature.

Fluid Level & Condition Check: With the system off and cylinders retracted, check the reservoir sight glass. Note the oil's color and clarity. Smell it—it shouldn't be burnt.

Performance Baseline: Know how your machine should perform. Note any gradual loss of speed or lifting capacity.

The Ultimate Prevention: Adhere strictly to the manufacturer's fluid and filter change intervals. Contaminated fluid is the leading cause of component wear and system failure.

Your hydraulic system communicates its health clearly. A strange noise, a slight performance drop, or a small leak are not problems to ignore "until the weekend." They are urgent whispers begging for attention. By training yourself and your team to recognize these 7 warning signs and implementing a routine inspection habit, you can transform from a victim of unexpected breakdowns into a master of predictive maintenance—saving thousands in repair costs and downtime.

Ready to take the next step? If you've noticed any of these signs, consult your machinery's service manual and contact a qualified hydraulic technician for diagnosis. Addressing a small issue today prevents a catastrophic failure tomorrow.